The Complete Guide to Freeze Dryers: What, Why & How — with Lanphan Solutions

In fields such as pharmaceuticals, food science, biotechnology, and research, maintaining product stability and integrity is paramount. A freeze dryer (also known as a lyophilizer) offers one of the best methods for preserving sensitive materials. In this guide, we’ll explore what freeze dryers are, their advantages, working principles, use cases, and why choosing the right freeze dryer matters — especially if you partner with a manufacturer like Lanphan.

What Is a Freeze Dryer?

A freeze dryer is a device that removes moisture from a material by converting ice directly to vapor (a process called sublimation), bypassing the liquid phase. First, the material is frozen; then, under vacuum, heat is gently applied so that the ice sublimates, leaving a dry product with minimal structural or chemical damage.

This method is fundamentally different from conventional drying or dehydration, which rely on heat and can degrade temperature-sensitive compounds.

Key Benefits of Freeze Drying

-

Preserves structure, texture & integrity: Because sublimation avoids liquid phase stresses, delicate structures remain intact.

-

Retains nutrients and active compounds: Heat-sensitive molecules (e.g. proteins, vitamins, drugs) are better preserved.

-

Longer shelf life / storage stability: Properly freeze-dried products can be stable for years if stored correctly.

-

Reduced weight, easier transport: Removal of moisture means lower weight and volume for shipping or storage.

-

Rehydration potential: Many freeze-dried products rehydrate nearly to their original state.

These advantages make freeze dryers essential in pharmaceuticals, research, food processing, biological sample preservation, and more.

How Does a Freeze Dryer Work?

Understanding the freeze drying process helps you choose or operate the equipment better. It typically follows these stages:

-

Freezing

The product is lowered to a sufficiently low temperature so that its water is completely frozen. -

Primary Drying (Sublimation)

Under vacuum, gentle heat is applied to drive ice to vapor directly (skipping liquid). Most of the water is removed here. -

Secondary Drying (Desorption)

To remove residual bound water, temperature is gradually raised (still under vacuum) to extract the remaining moisture.

Key parameters to control include condenser temperature, shelf (or product) temperature, vacuum level, and time.

One user on a lab forum summarized it well:

“The freeze dryer starts by deeply freezing the material and then zaps out the air. This tricks the ice, turning it directly into vapor, which skips the melty puddle stage.”

Applications & Use Cases of Freeze Dryers

Freeze dryers are versatile and used across many industries:

| Sector | Typical Use Cases |

|---|---|

| Food / Nutrition | Fruits, vegetables, powders, ready meals, snacks |

| Pharmaceuticals | Vaccines, injectables, biologics, antibiotics |

| Biotechnology / Research | Enzymes, proteins, cell cultures, reagents |

| Diagnostics / Kits | Reagents, assay components |

| Botanical / Herbal | Plant extracts, essential oils, herbs |

| Preservation & Museums | Specimens, biological samples |

Because freeze drying is gentle and non‑destructive, materials that would degrade by heat drying can be preserved effectively.

Key Factors to Consider When Choosing a Freeze Dryer

If you’re evaluating a freeze dryer (or upgrading), these are critical criteria:

| Parameter | Why It Matters |

|---|---|

| Capacity & Throughput | Determines how much material you can process per batch |

| Condenser / Cold Trap Temperature | Lower temps enable handling high-moisture loads |

| Vacuum Performance | Strong vacuum speeds up sublimation and reduces residual moisture |

| Heating / Shelf Control | Precise control avoids overheating or under-drying |

| Uniformity & Heat Transfer | Ensures consistent drying across all trays or vials |

| Chamber Geometry & Tray Design | Influences load layout, airflow, and ease of loading |

| Control & Automation | Programmable cycles, sensors, alarms, and data logging |

| Material & Construction | Stainless steel, corrosion resistance, ease of cleaning |

| Scalability / Modular Design | Ability to grow as demand increases |

| After‑sales Support & Maintenance | Critical for uptime in industrial or critical labs |

Choosing a freeze dryer is not just about cooling power or vacuum — the integration, control, and design details often make the difference.

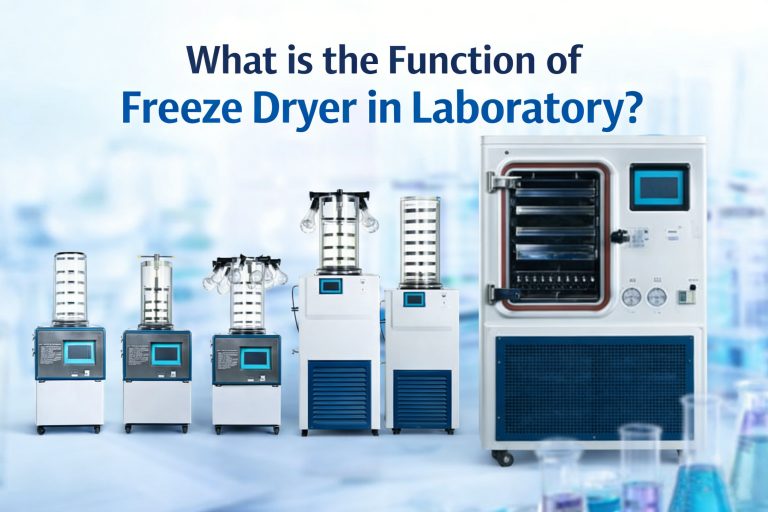

Why Choose Lanphan’s Freeze Dryers?

Here’s what sets Lanphan freeze dryer solutions apart:

-

We offer a complete line of freeze dryers with varying capacities, from research lab scale to larger production units.

-

Our designs include precise control systems, reliable vacuum systems, efficient refrigeration, and robust construction.

-

We ensure clean, corrosion-resistant materials ideal for pharmaceutical, food, and biological use.

-

Customization and modular expansions are possible to match your workflow.

-

Strong after-sales support, spare parts, and training assistance help you maximize uptime.

For full details and product specifications, check out our Lanphan Freeze Dryer page: https://www.lanphan.com/freeze-dryer/

Tips & Best Practices for Operating Freeze Dryers

-

Pre-freeze your samples well (to avoid ice layering)

-

Use thin, uniform slices/trays to ensure consistent drying

-

Avoid mixing dissimilar materials in the same cycle (they may have different drying rates)

-

Monitor vacuum, temperature, and time carefully

-

Don’t overload trays — leave clearance for vapor flow

-

Gradually ramp temperature to avoid collapse

-

Clean the chamber and condenser routinely

-

Use appropriate vacuum traps or guard systems to protect the vacuum pump

-

When drying sticky or high-fat materials, special care is needed (they may block channels)

Conclusion

A freeze dryer is a powerful tool in the preservation and processing pipeline, providing unmatched quality for heat-sensitive or structurally delicate materials. Whether in food science, pharmaceuticals, biotech, or research, selecting a high‑quality, well-engineered freeze dryer is crucial for performance and reproducibility.

At Lanphan, we blend engineering excellence, flexibility, and strong support to deliver freeze dryer systems tailored for your needs. Explore our product catalog and begin a conversation: