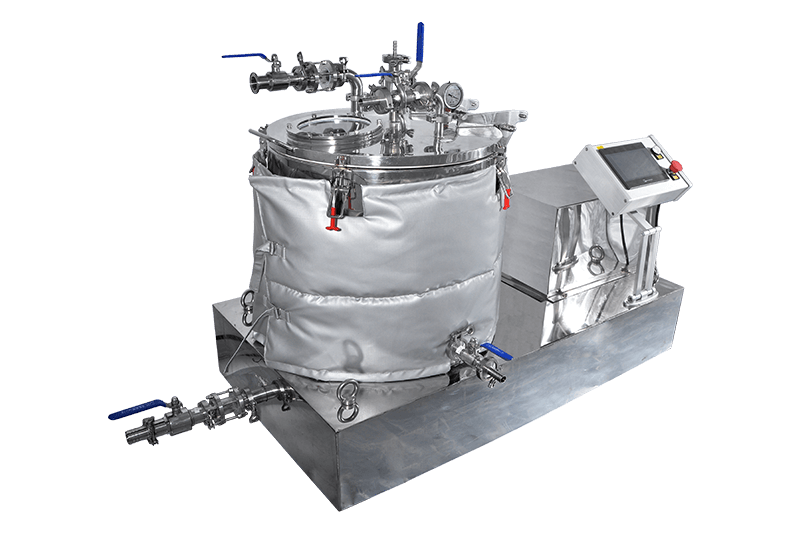

Ethanol Extraction Machine

1.Low temperature range -50℃ to 50℃

2.Large sight glass structure, clear view of the situation inside the equipment.

3.Fully automatic extraction process, the program can set the forward and reverse rotation speed of the drum, time andnumber of cycles, dehydration speed and time, and can be switched to manual control.

4.Temperature display.Pressure display.

5.Zippered filter bag can be quickly loaded and unloaded.

6.There are also optional configurations: oxygen content detection and protection system, cart structure.

| Technical Data | PP15 | PP25 | PP45 | PP60 | PP110 | PP140 | PP250 |

| Material volume | 15L | 25L | 45L | 65L | 115L | 145L | 250L |

| Rotating speed | 2000r/min | 2000r/min | 1500r/min | 1500r/min | 1250r/min | 1250r/min | 1100r/min |

| Motor power | 1.1kw | 1.5kw | 2.2kw | 3kw | 4kw | 5.5kw | 11kw |

| Loading quantity per batch | 3kg | 5kg | 10kg | 12kg | 23kg | 28kg | 50kg |

| Package Size | 1100x650x1020 | 1100x650x1020 | 1400x850x1080 | 1400x850x1080 | 1600x1060x1250 | 1600x1060x1330 | 1700x1400x1600 |

| Package weight | 240kg | 260kg | 380kg | 410kg | 800kg | 820kg | 1350kg |

Stainless Steel Storage Tank

lt is a stainless steel container used to store liquids and can be equipped witha refrigeration pump to cool the liquid through the inter layer.

| Technical Data | ST-B50 | ST-B100 | ST-B200 | ST-B300 | ST-B500 | ST-B1000 |

| Volume(L) | 50 | 100 | 200 | 300 | 500 | 1000 |

| lnner diameter(mm) | 400 | 500 | 600 | 800 | 900 | 1000 |

| Design pressure (Mpa) | 0.1-ATM | |||||

| Jacket pressure resistance (Mpa) | ATM-0.3 | |||||

| Design temperature(℃) | ‐80‐200 | |||||

| Material | SUS304 | |||||

| Standards compliant | GMP | |||||

Chiller

lt is a low-temperature liquid circulation equipment using mechanical refrigeration,which can provide constant flow and constant pressure circulating cooling liquid toreduce the operating temperature of the instrument.

| Technical Data | DLSB100L‐80℃ | DLSB150L‐80℃ | DLSB200L‐80℃ |

| Minimum temperature without load | ‐80℃ | ||

| Temperature fluctuations | ±2℃ | ||

| Refrigeration capacity | 520W‐15230W | 680W‐19860W | 490W‐24000W |

| Machine power | 280W | ||

| Circulation pump flow (optional) | 35L | 40L | 35L |

| Water-lift (optional) | 13M | 18M | 11M |

| Power supply | 380V50HZ (Three-phase power) | ||

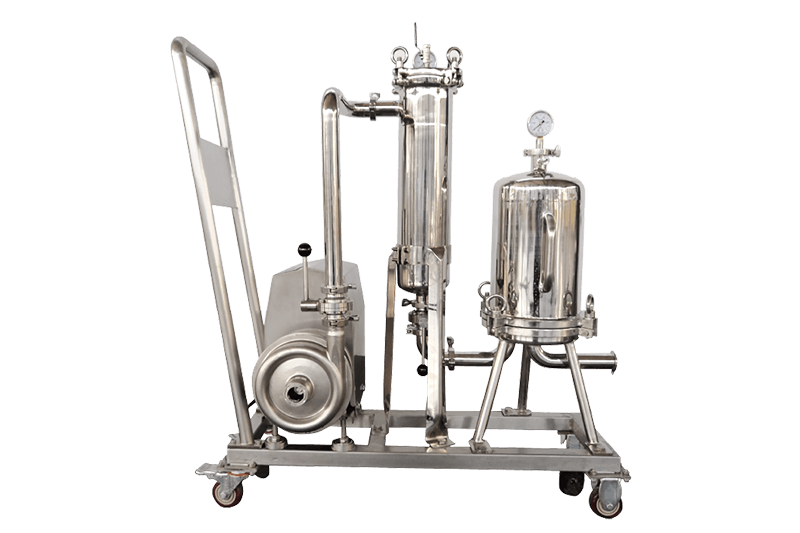

Filter

lt is used for rapid filtration of oils, resins, tinctures. lt is a modular solution forwashing the solvent stream obtained after passing plant biomass through acentrifugal separator.

| Technical Data | 3T | 5T |

| Filtration speed | ≤3T/H | ≤5T/H |

| Pump | Sanitary centrifugal pump (5T/H) | |

| Voltage | 220V/50Hz | |

| First level | Side-entering bag filter (4#) | Side-entering bag filter (1#) |

| Second level | Multi-core liquid filter (10″x3) | Multi-core liquid filter (20″x3) |

| Structural material | 304 | |

Falling Film Evaporator

The function of falling film evaporator is to separate the ethanol from materialand condense and recover it through reduced pressure vacuum and evaporation.lt is widely used in food, dairy, chemical, biological engineering, environmentalprotection engineering and corn deep processing.

| Technical Data | FFE-50 | FFE-100 | FFE-200 |

| Evaporation rate (L/H) | 50 | 100 | 200 |

| Heating area (m2) | 3 | 5 | 12 |

| Condensation area (m2) | 5 | 7.5 | 16 |

| Feed pump (kw) | 0.55 | 1.1 | 1.5 |

| Discharge pump | 0.55 | 1.1 | 1.5 |

| Discharge pump | 0.55 | 1.1 | 1.1 |

| Water circulating vacuum pump (kw) | 0.81 | 0.81 | 1.5 |

| Total power | 2.46 | 4.11 | 5.6 |

| Power supply | 220V/60Hz Three-phase power, can be customized | ||

| Cooling water volume (t/h) | ≥5.5 | ≥11 | ≥22 |

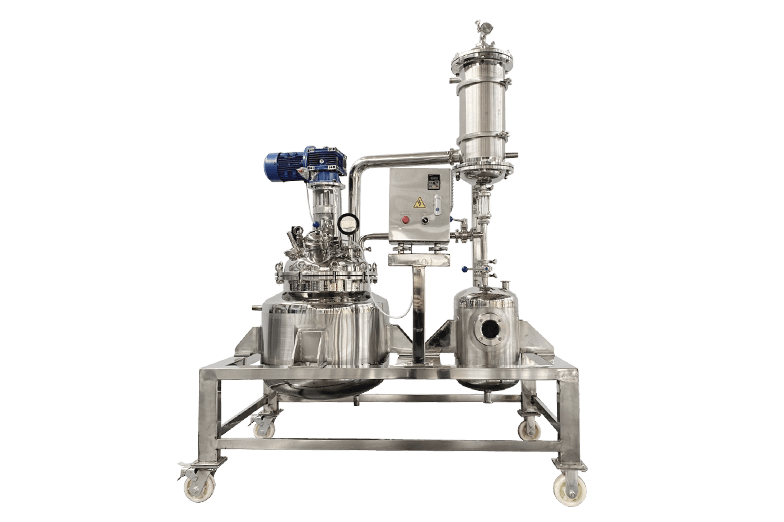

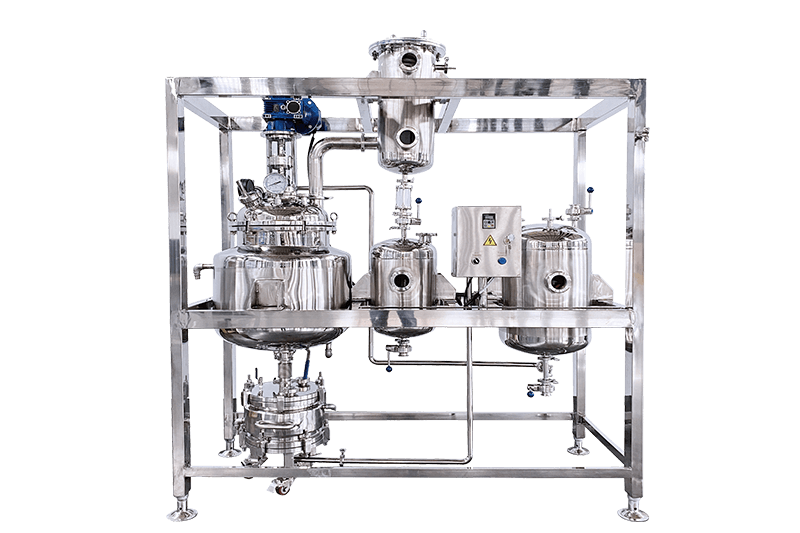

Stainless Steel Decarboxylation Reactor

1.The whole machine is made of metal, which has better heat exchange effect.Parts in contact with materials are made of sanitary grade sUS316 material,which has good corrosion resistance.

2.With high-power mixing motor

3.UL certified mixing motor and UL certified control box can be selectedaccording to customer needs.

| Model | SDS-50 | SDS-100 | SDS-200 |

| Reactor volume | 50L | 100L | 200L |

| Collection tank volume | 20L | 30L | 80L |

| Condenser | 0.5㎡ | 1㎡ | 2㎡ |

| Reaction Temperature of Kettle Body | -80~250ºC | ||

| Ultimate Vacuum | -0.098Mpa | ||

| Stirring Speed | Frequency 0-120rpm | ||

| Stirring Power | 0.5kw | 0.75kw | 1.1kw |

| Voltage /Frequency(V/Hz) | 220V/380V/480V | ||

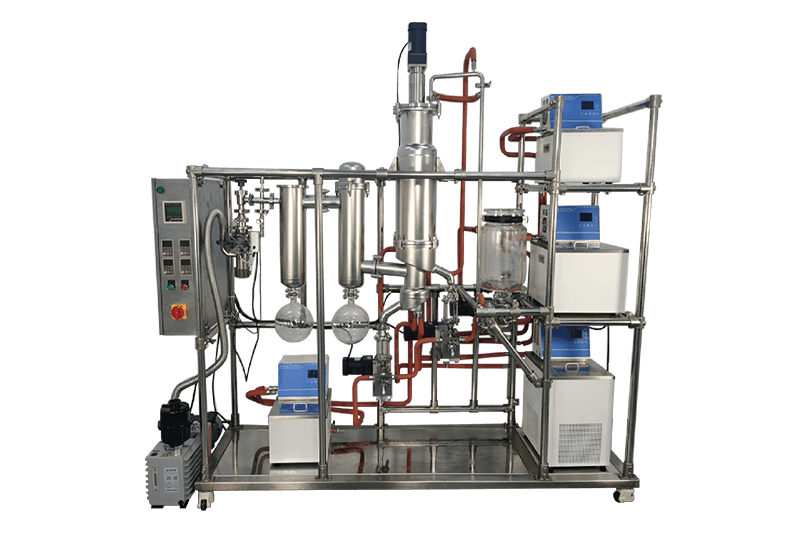

Wiped Film Distillation

Wiped film distillation is a special liquid-liquid separation technology, which isdifferent from the traditional distillation based on the separation principle ofmaterial boiling point difference, but based on the difference in the mean freepath of molecular motion of each material in the mixture to achieve separation.

| Model | FMD-0.1SS | FMD-0.15SS | FMD-0. .25SS |

| Effective evaporation area | 0. 1㎡ | 0.15㎡ | 0.25㎡ |

| Condensation area (m) | 0.17 | 0.3 | 0.4 |

| Feeding speed (L/H) | 5-12 | 6-15 | 10-25 |

| Speed(r/min) | 30-350 | ||

| Stainless steel material | 304/316 | ||

| Feeding method | Gear pump, continuous feeding | ||

| Discharging method | Gear pump, continuous discharging | ||

| Operating temperature (℃) | Within 350℃ | ||

| Voltage | 220V/50Hz other voltages can be customized | ||

Stainless Steel Crystallization Reactor

lt is an ideal equipment for crystallization, which combines the dual functionsof the reactor and the filter. The stainless steel crystallization reaction kettle isconnected with a vacuum filtration device,which is often used for the crystallizationand filtration . lt can realize constant high or low temperature inside the kettle body.

| Product model | SCR-50 | SCR-100 | SCR-200 |

| Kettle volume | 50L | 100L | 200L |

| Recovery tank volume | 20L | 40L | 80L |

| Collection tank volume | 50L | 80L | 150L |

| Condenser | 0.5㎡ | 1㎡ | 2㎡ |

| Filter | 20L | 30L | 60L |

| Filtration accuracy | 15-40um | ||

| Kettle reaction temperature | -80~250ºC | ||

| Ultimate vacuum degree | -0.098Mpa | ||

| Stirring speed | Frequency control speed 0-120rpm | ||

| Voltage | 220V/380V | ||

| Stirring power | 0.5kw | 0.75kw | 1.1kw |

Get a quote now!

What is the method for ethanol extraction?

Ethanol extraction is a method used to extract compounds, such as cannabinoids from plants, including cannabis.

It’s essential to exercise safety precautions during ethanol extraction due to the flammability of ethanol. Additionally, compliance with local regulations and standards, especially in industries like cannabis extraction, is crucial.