Tablet Press Machines for Pharmaceutical Production: Efficient and Reliable Pill Manufacturing Solutions

What is a Tablet Press?

A tablet press machine is a critical device in the pharmaceutical and nutraceutical industries for manufacturing solid oral medications. The primary function of a tablet press is to compress powders or granular substances into solid, uniform tablets with defined shapes and sizes. This process is essential in producing medicine that is easy for patients to administer.

In the pharmaceutical industry, tablet press machines are used to produce single-layer or multi-layered tablets, which are then packaged and distributed to ensure consistent dosage and potency. The operation of a pharmaceutical tablet press involves several stages, including feeding, compression, and ejection, each designed to ensure the quality and efficacy of the final product.

How Does a Tablet Press Work? The Process of Tablet Pressing

The tablet press machine operates through a multi-step process, ensuring uniformity and precision in tablet manufacturing.

Feeding Stage

Medicinal ingredients in the form of powder or granules are introduced into the feeding system of the tablet press.

Pre-Compression Stage

At this stage, a certain pressure is applied to the medicinal ingredients, forming an initial compression within the mold. This step ensures uniformity and consistency of the tablets.

Main Compression Stage

In this phase, higher pressure is applied to the medicinal ingredients, shaping the final tablets within the mold. This ensures that the tablets have the desired shape and size.

Ejection Stage

The formed tablets are ejected from the mold, preparing for the next round of tablet production. This may involve vibration or other mechanical means.

Types of Tablet Press Machines

We offer a range of tablet press machines designed to suit different production needs. Whether you’re looking for a single punch tablet press for small batches or an industrial tablet press for large-scale manufacturing, we have a solution for you.

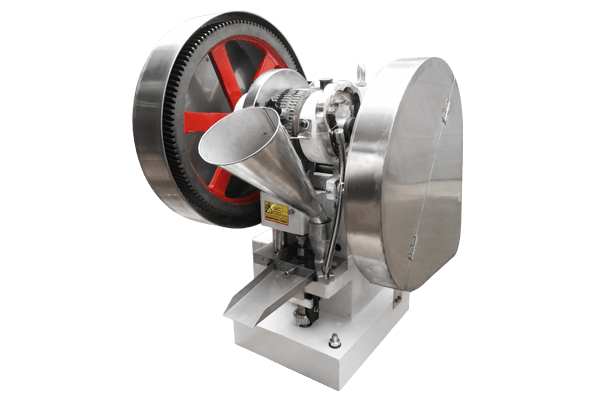

Single Punch Tablet Press

A single-charging tablet press is a pharmaceutical industry device primarily designed for the production of single-layer tablets or solid formulations. In comparison to other types of tablet presses, the distinctive feature of a single-charging tablet press lies in its ability to fill the entire mold at once, forming consistently single-layer tablets.

Multiple Punch Tablet Press

A multi-station tablet press is a pharmaceutical device used to conduct multiple tabletting actions within a single pressing cycle, resulting in the production of multi-layered solid tablets or pills. Compared to traditional single-station presses, multi-station presses offer enhanced production efficiency and more flexible tablet manufacturing capabilities.

Key Components of a Tablet Press Machine

- Molds: Define the shape and size of the tablets.

- Feeding System: Introduces the medicinal ingredients into the tablet press.

- Pressure System:Provides the necessary pressure, typically through pressure rollers or rods.

- Control System: Monitors and adjusts parameters such as pressure and speed to ensure the quality and consistency of the tablets.

Why Choose Lanphan Tablet Press Machines?

Our tablet press machines are engineered with precision and efficiency to ensure superior tablet production. Key features of our pharmaceutical tablet presses include:

- High Production Capacity: Perfect for small to large-scale manufacturing.

- Customizable Pressing Options: Adjustable settings to suit various formulations and tablet specifications.

- Robust and Durable Construction: Built to withstand heavy-duty use in industrial environments.

- User-Friendly Interface: Simplifies operation and minimizes downtime.

- Precise Tablet Consistency: Ensures uniform hardness, size, and weight for each tablet.

Industrial Tablet Press Machines for Reliable Pill Production

Why Choose Our Tablet Press Machines?

• 30% Faster Output – Produce 5,000-20,000 tablets/hour with ≤0.5% weight variation

• Zero Downtime – Stainless steel body, German-made hydraulic system

• Plug & Play – Pre-calibrated settings for 10+ common materials (e.g., vitamin C, ibuprofen)

• Your Safety First – Auto-shutdown for overload/blockage (CE & ISO 13485 certified)

Key Features of Lanphan Tablet Press

Core Specs

✓ Max Pressure: 10-100 kN (adjustable via touchscreen)

✓ Tablet Size: 5-25 mm diameter, 1-10 mm thickness

✓ Noise Level: <65 dB

Smart Add-Ons

✓ Batch Data Export (USB/Bluetooth)

✓ Multi-layer Tablet Mode

✓ Remote Troubleshooting Port

Tablet Press Applications

Pharmaceutical

• Prescription drugs: Coated/uncoated pills, effervescent tabs

Health Supplements

• Calcium/Probiotics in tablet/capsule form

Food Industry

• Candy mints, seasoning cubes, pet food supplements

10+ Years of Customer Success

”Switched from manual to lanphan press last year. Now our Vietnam factory makes 8M vitamin tablets monthly with 2 operators.”

– James Lee, NutraHealth Malaysia

”Their engineers helped us pass FDA audit in 3 weeks.”

– Sophia R., PharmaStart Chile

Request a Quote for Your Tablet Press Today

If you’re looking for a tablet press machine for your manufacturing needs, get in touch with us today to receive a customized quote. Our team is here to assist with choosing the best solution for your production requirements.

Tablet Press Videos

Frequently Asked Questions (FAQ) About Tablet Press Machines

What is the cost of a tablet press machine?

The cost of a tablet press machine depends on several factors, including the type, production capacity, and specific features. Contact us for a customized quote based on your needs.

How do I choose the right tablet press for my business?

The right tablet press machine depends on factors such as the volume of tablets you need to produce, the type of tablets, and the desired production speed. Our team can help you select the best option.

Can I use a tablet press machine for both pharmaceutical and food products?

Yes, our tablet press machines are versatile and can be used in both pharmaceutical and food industry applications. Specific adjustments can be made to accommodate different tablet formulations.