Why is Freeze-Drying Expensive? Understanding the Costs Behind the Process

Freeze-drying, also known as lyophilization, is a method used to preserve perishable items such as food, pharmaceuticals, and biological samples. While it offers numerous benefits like extended shelf life and preservation of flavor and nutrients, one question often arises: why is freeze-drying expensive? Let’s delve into the factors that contribute to the high costs associated with this process.

The Intricacies of Freeze-Drying

Freeze-drying involves several intricate steps that require specialized equipment and expertise. The process begins by freezing the material to solidify it, followed by the removal of ice through sublimation under vacuum conditions. This transforms the frozen water directly into vapor without passing through the liquid phase, preserving the structure and integrity of the material.

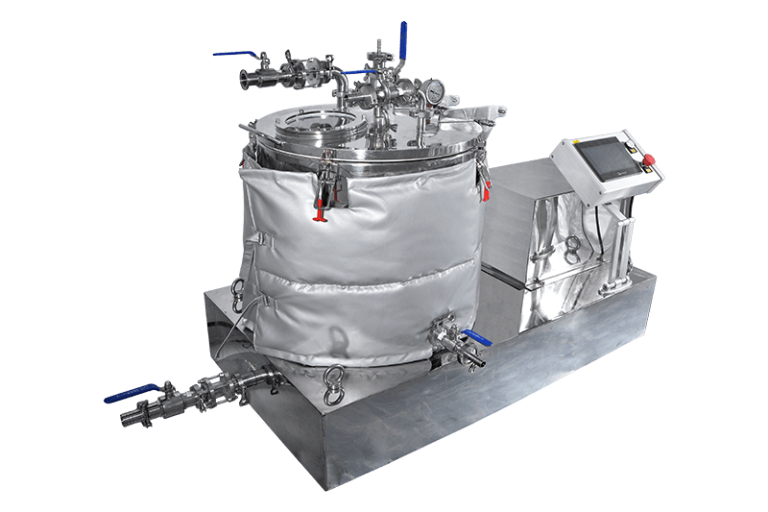

Investment in Equipment

One significant reason for the high cost of freeze-drying is the investment in specialized equipment. Freeze-dryers, also known as lyophilizers, are complex machines that require precise control over temperature, pressure, and humidity. These machines come in various sizes and configurations, with prices ranging from thousands to millions of dollars depending on capacity and features.

Energy Consumption

Freeze-drying is an energy-intensive process. Maintaining low temperatures during freezing and sublimation requires continuous refrigeration and vacuum systems, which consume significant amounts of electricity. The duration of the process can also vary depending on the material being dried, further contributing to energy costs.

Labor Intensity

Another factor driving up the cost of freeze-drying is the labor-intensive nature of the process. Skilled technicians are required to operate and monitor the equipment throughout the drying cycle. Additionally, the preparation of materials, loading and unloading of trays or shelves, and post-drying packaging all require human intervention, adding to the overall expenses.

Raw Material Costs

The cost of raw materials also plays a role in the expense of freeze-drying. High-quality ingredients or products that undergo freeze-drying, such as gourmet foods or pharmaceuticals, can be expensive to procure. Furthermore, any loss or waste during the process contributes to the overall cost per unit of the final product.

Quality Assurance and Regulatory Compliance

Ensuring product safety and quality is paramount in industries that utilize freeze-drying. Stringent regulatory requirements, such as Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP), necessitate robust quality assurance and control measures. Compliance with these standards adds additional costs to the production process.

Scale of Operations

The scale of freeze-drying operations also impacts costs. Large-scale facilities with higher throughput and economies of scale may be able to offer lower prices per unit compared to smaller operations. However, establishing and maintaining such facilities requires substantial initial investment, which can still contribute to higher overall costs.

Transportation and Storage

Once the freeze-drying process is complete, the finished products must be transported and stored under controlled conditions to maintain their quality and stability. This includes packaging materials, temperature-controlled transportation, and warehousing facilities, all of which add to the total cost of the product.

Market Demand and Pricing

Finally, market demand and pricing dynamics influence the cost of freeze-dried products. Items with high demand or limited availability may command higher prices, reflecting supply and demand forces in the market. Additionally, the perceived value of freeze-dried products, particularly in niche markets like gourmet foods or specialty pharmaceuticals, can justify premium pricing.

Conclusion

In conclusion, why is freeze-drying expensive? The high costs associated with this process stem from a combination of factors, including the investment in specialized equipment, energy consumption, labor intensity, raw material costs, quality assurance measures, scale of operations, transportation and storage requirements, and market dynamics. While freeze-drying offers numerous benefits in terms of product preservation and quality, these benefits come at a price. However, understanding the factors driving the costs can help consumers and businesses alike appreciate the value that freeze-dried products offer.

Curious to learn more about the fascinating world of freeze-drying? Explore advanced techniques and innovative applications in our next article! Keep reading to discover how freeze-drying is shaping industries and revolutionizing the way we preserve and consume perishable goods.