What is the Process of Ethanol Extraction?

Ethanol Extraction remains one of the best methods of managing botanical processing in the world.

The technique has been adopted in the pharmaceutical and food industries in several decades, but has found growth in the contemporary herbal and cannabinoids extraction. It is famed to be efficient, cost effective and capable of storing fragile compounds.

However, how is ethanol extraction carried out? Why is it appealing as compared to other approaches?

Understanding the Basics of Ethanol Extraction

Ethanol is a solvent with polar molecules. It implies that it has the ability to solve even water-soluble and also fat-soluble compounds.

It is applied in extraction where it is used to draw the cannabinoids, terpenes, flavonoids, and other useful components of a plant. Due to its efficiency, this approach has been spread in all sectors.

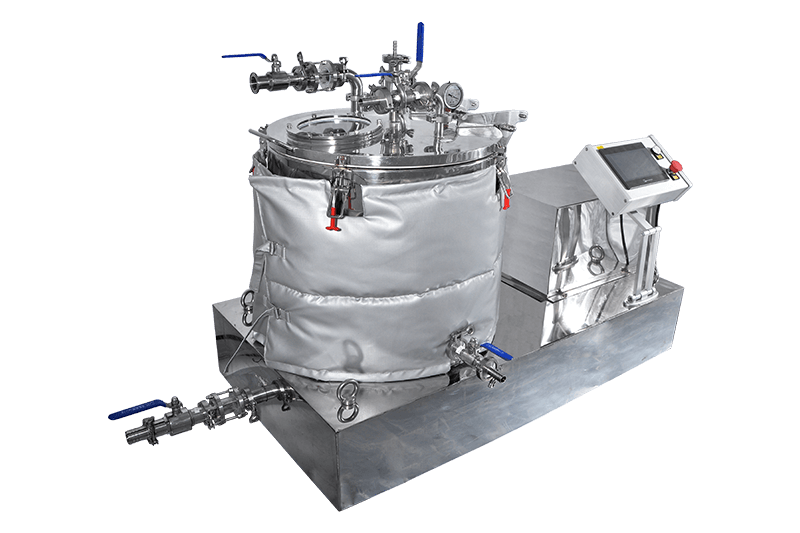

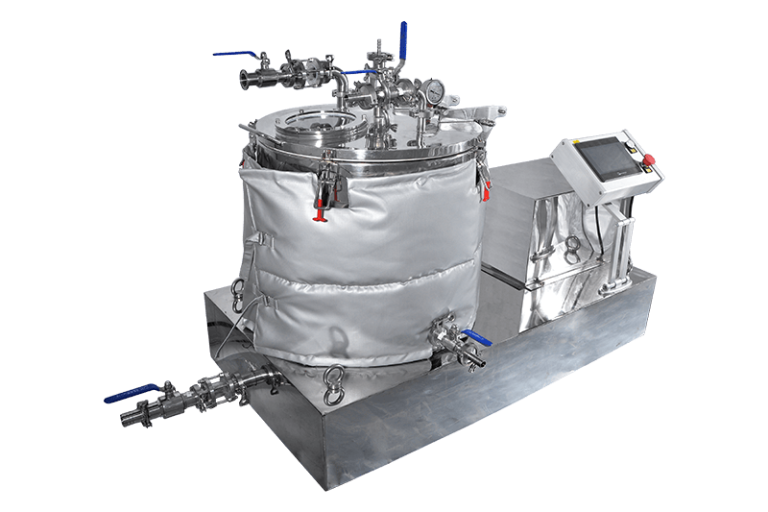

The action is conducted with the aid of special gear that is capable of handling ethanol safely and efficiently. Firms such as Lanphan have come up with innovative products that are assisting companies to sustain increased production requirements.

Step 1: Preparing the Biomass

It all starts with the material of the plant-usually known as a biomass.

It should be ground and dried up before extraction. This enhances surfaces and better penetration of the solvent.

Less water is excluded to keep moisture content in the biomass to a minimal conducive level because excessive amounts of water are likely to limit efficiency and purity.

Pre-chilling of the material is undertaken in certain systems as well. This assists in avoiding undesired compounds, such as chlorophyll, to be extracted.

Step 2: Chilling the Ethanol

The most suitable is cold ethanol.

In the majority of installations, ethanol is cooled down to below freezing temperatures, even up to -40 o C.

What is wrong with being cold?

At low temperatures, waxes, fats, and chlorophyll can not be extracted. The result is organized and more refined since less post-processing is required.

Other systems incorporate a chilling unit and there are still others that external chillers are used. It varies according to the size of the production.

Step 3: Extraction Phase

It is here that the magic takes place.

The ethanol at a chilled temperature is added to the biomass. The duration of contact differs (a few minutes-an hour) upon purity according to the desire and set up.

The mixture is then agitated lightly so that the solvent penetrates completely. At this stage, the ethanol dissolves the active compounds.

It is like tiptoeing. Extended contact has the ability to draw more cannabinoids but can also draw nun-wantables.

Automated ethanol extract sound-systems can be useful in this aspect to ensure that time, temperature, and agitation is controlled.

Step 4: Filtration

The mixture will also require separation after soaking.

This leaves out the solid biomass, usually, by mesh screens and filter bags. This results in a solution that has concentrated compounds.

In some systems filtration is done inline and this saves time and labor. Some people require different vessels to do this step.

It is important that this step should be made out. The final product can be interfered with by any residue left in plants.

Step 5: Solvent Recovery

Ethanol has to be purged now.

This solution is then introduced into a recovery system and evaporation with the help of a vacuum is usually involved. This ensures lower boiling points of ethanol.

The amount of ethanol recovered is condensed and re-used. The majority of the set-ups are capable of recovering more than 95 percent of the solvent.

It is not only economical but also friendly to the environment. Actually, some firms interested in expanding in a responsible way frequently buy high-efficiency recovery systems. The broad selection of such options is discretely explained at the Lanphan site here.

Step 6: Post-Processing

The resulting oil does not always become ready to use.

It may still have lipids, or waxes, or chlorophyll. In order to purify it, additional removal procedures such as winterization and distillation are involved.

Winterization entails redissolving extract crude in ethanol once again with freezing. This makes waxes and fats solidify and are filtered out.

The compounds are then distilled to obtain the desired ones. This leads to a very clean report which can be used as tincture, capsules or vapor products.

Why Choose Ethanol Extraction?

Ethanol extraction has dominated so many reasons:

Scalability: It can fit small-scale labs and large large-scale industrial factories.

Safety: The food grade ethanol is usually safe and can be manipulated without any difficulties.

Cost effective: Ethanol can be recycled and it is also very common.

Multifunctionality: one pass extracts a wide variety of compounds.

The process of ethanol extraction is cleaner and simpler compared to other ways such as CO 2 extraction, or hydrocarbon extraction, for instance.

That’s why manufacturers often seek expert suppliers with proven track records. It’s no surprise that companies such as Lanphan are leading the market in reliable ethanol extraction solutions.

Common Misconceptions

There are those that suggest that extracting using ethanol will always remove unwanted chlorophyll or the waxes. That was the case with warm ethanol but this is substantially eliminated with cold ethanol.

It occurs to some people as being risky-however, the modern, closed-loop systems make the process very safe.

Though others allege that it is not as accurate as CO 2 extraction, refined ethanol systems are demonstrating otherwise. Ethanol provides a steady, strong and clear extract when handled well.

Final Thoughts

Ethanol extraction is a technique that is a union of science, technology, and precision.

Each process is important, whether processing the biomass to the process of recovering the solvent. And provided by the proper equipment and process control, the process brings marvellous results.

Companies venturing or expanding in the extraction sector ought to look beyond ethanol as a solvent- they ought to view ethanol as a complete solution. The benefits are self-explicable.

When you are thinking about using ethanol systems, be it a new system or retrofitting your current system, the first place to look is the suppliers that are trusted in this industry such as Lanphan. The systems that they provide are suitable to both start-up and industrial requirements as indicated in their site.