What is a labeling machine used for?

A labeling machine is used to affix labels onto products, packaging, or other items. It’s commonly employed in commercial and industrial settings to convey vital information such as product names, specifications, production dates, barcodes, prices, and more. By enhancing production efficiency and reducing labor costs, labeling machines ensure the accuracy and consistency of labels, making them an indispensable component of modern assembly lines.

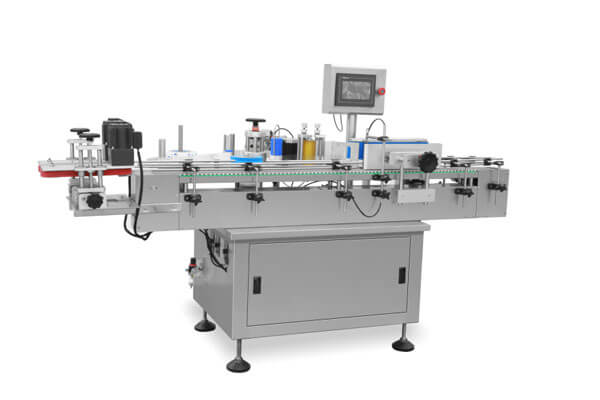

Automatic Labeling Application Machine

We employ a pre-positioning label system to ensure stable label dispensing, smooth labeling, and precise positioning.

Our equipment operates smoothly and is easy to use thanks to the touchscreen interface and PLC control system.

Our tensioning design not only ensures high-quality printing but also accurately controls label length and uniformity of application.

Different bottle types are catered for with tailored roller-press label application methods, ensuring consistent labeling quality.

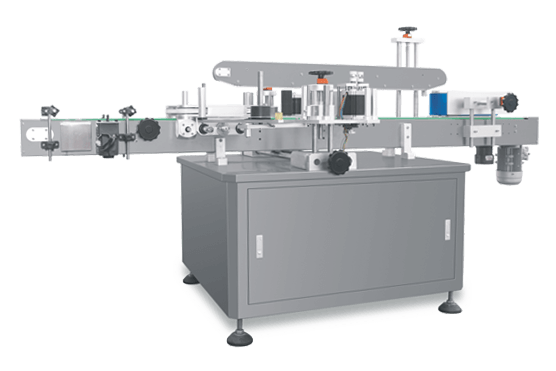

LP-T2Multi-function labeler

- User-Friendly Operation: The touch screen interface and PLC control system make operation and maintenance simple.

- Automated Detection System: It detects bottle absence, label absence, ribbon absence, and bottle shortage, ensuring accurate labeling.

- Stable Labeling with Optical Control: Labels are applied steadily and reliably with adjustable positions, thanks to the optical control drive.

- High-Quality Labeling: The pre-labeling system ensures stable output, smooth labeling, and precise positioning.

- Tensioned Paper Design: Ensures quality printing and uniform paper length and positioning.

- Versatile Adaptability: Different bottle types are accommodated with tailored structural approaches, ensuring reliable labeling quality.